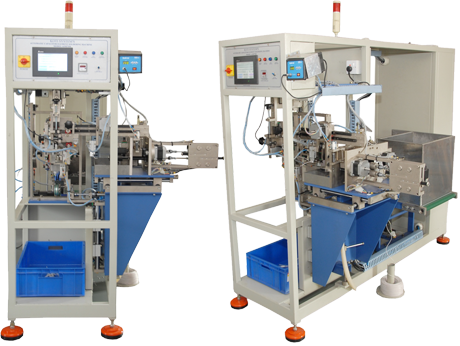

This machine is used for soldering multi stranded wires to capacitor elements. In this machine wires can be cut from 40mm up to 300mm in length and it de sleeves in the soldering side. Free end of the wire can be stripped, either jacket type or full length de sleeve. In this machine, elements from hopper bowl will be picked from the robot and carried to the place where soldering takes place.

Wire of the program length will be fed from wire pick up robot on to surface and fed to the wire holding jaws at the soldering place. Solder gun comes down on to the surface of the element, simultaneously solder wire also fed to the tips of solder gun. Here programmed length of solder wire will be fed with help of stepper motor. Importance of the stepper motor in this position is to feed consistent and programmed length of solder wire. Element will be reversed after this process. After reverse wire feeding and soldering will be repeated. Finally element will be ejected at the same place and cycle will be repeated if auto mode is on.